Doctor Blade Assemblies

Made to order to meet any need.

Doctor Blade Assemblies made by Tape Casting Warehouse, Inc. , now also available through TCW-Europe) have been proven in use for over 20 years.

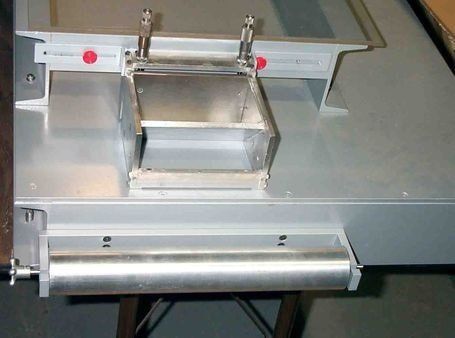

A spark-proof, lightweight, all aluminum housing is designed to ride directly on the carrier film. This avoids thickness variations from carrier thickness variation and gives a stable blade gap setting.

The Blade Gap is set using two micrometers per blade, each marked in 0.0001″ increments. Dual micrometer adjustment gives control over blade gap as well as blade levelness.

The Blade itself is made of stainless steel and surface ground and polished for flatness. The steel blade provides excellent abrasion resistance against the ceramic slip at normal and even high casting speeds.

For those casting on steel belt machines, the doctor blade housing may be made of Delryn®/Teflon® to avoid marring the continuous belt.

The reservoir design makes this doctor blade assembly function excellently for stationary blade/moving carrier machines, moving blade machines as well as for hand-drawn casting.

The back wall of the reservoir is set at a 45º angle which allows “low impact” slip additions to the reservoir. This helps to avoid green tape thickness variation due to changing forces on the reservoir head.

The doctor blade assembly is also designed in such a way that both single and double doctor blade assemblies have the same outside dimensions to allow easy changeover. Fixed gap doctor blades are also available.

All blades are made to order by TCW-USA, and can thus be any desired inside width, English or metric.